How to Maximize Vacuum Circuit Breaker Performance

A vacuum circuit breaker is a vital component in industrial, commercial, and utility electrical systems, providing reliable protection against overloads and short circuits. To ensure safety, reliability, and longevity, it’s important to maximize the performance of your Vacuum circuit breaker. This guide explains key strategies and best practices to achieve optimal results.

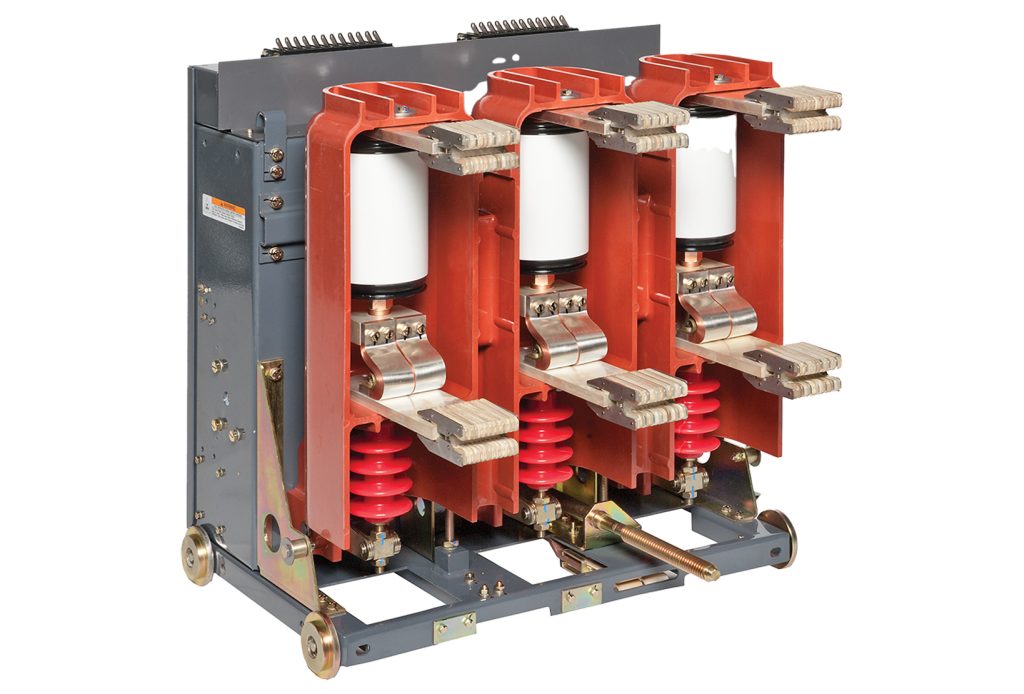

Understanding Vacuum Circuit Breaker Operation

A vacuum circuit breaker interrupts electrical current by extinguishing arcs in a vacuum chamber. This design prevents contact oxidation, reduces wear, and minimizes maintenance needs. Proper operation of a vacuum circuit breaker ensures that electrical systems remain safe and reliable, even under high load or fault conditions.

Key Factors to Maximize Performance

1. Correct Selection of Breaker Rating

Selecting a vacuum circuit breaker with the correct voltage and current ratings is critical. Using a breaker rated too low may lead to failure during fault conditions, while an oversized breaker can be inefficient. Matching the vacuum circuit breaker to system specifications ensures optimal performance and safety.

2. Proper Installation

Incorrect installation can reduce the effectiveness of a vacuum circuit breaker. Ensure proper alignment, tight electrical connections, and adherence to manufacturer guidelines. Correct installation enhances mechanical operation and arc interruption reliability, preventing unnecessary wear or malfunctions.

3. Regular Preventive Maintenance

Although vacuum circuit breakers require minimal maintenance, periodic inspection is essential. Check for signs of wear, inspect vacuum interrupters, and test mechanical operations. Preventive maintenance helps maintain the vacuum circuit breaker’s reliability and extends its operational life.

4. Environmental Considerations

Operating conditions affect vacuum circuit breaker performance. Protect the breaker from extreme temperatures, moisture, dust, and corrosive environments. Using enclosures or selecting a model designed for harsh conditions ensures the vacuum circuit breaker operates efficiently over time.

5. Monitoring and Testing

Regular performance monitoring and testing improve vacuum circuit breaker reliability. Conduct routine electrical and mechanical tests, verify trip settings, and monitor operating conditions. Proactive monitoring helps detect potential issues before they affect system performance.

Benefits of Maximized Vacuum Circuit Breaker Performance

Maximizing vacuum circuit breaker performance provides several advantages:

- Enhanced safety and faster fault interruption

- Reduced downtime due to fewer maintenance issues

- Extended operational life of the breaker and connected equipment

- Reliable operation in industrial, commercial, and utility applications

Properly maintained and optimized vacuum circuit breakers contribute to overall system efficiency and protection.

Applications Across Industries

Vacuum circuit breakers are widely used in industrial plants, power generation facilities, commercial buildings, and utility substations. Optimized performance ensures protection of critical equipment such as transformers, motors, and distribution networks. By maximizing vacuum circuit breaker performance, industries can maintain safe, efficient, and uninterrupted operations.

Conclusion

Maximizing vacuum circuit breaker performance requires correct selection, proper installation, regular maintenance, and environmental considerations. By following these best practices, you ensure fast fault interruption, extended service life, and reliable protection for your electrical system. Investing time and resources into optimizing a vacuum circuit breaker guarantees long-term safety, efficiency, and uninterrupted operation for industrial and commercial applications.